A brief comparison of WOWO transmitters and their technology.

The Westinghouse 50HG transmitter is a high level plate modulated transmitter. Essentially, the modulator is

a high powered (25,000 Watts), audio amplifier which adds an audio variation to the plate supply voltage for the

RF final, modulating the amplitude of the RF carrier. This requires huge, lossy transformers and tubes operated

in active (somewhere between cutoff and saturation) states. In this region of operation, you have a voltage across

the tubes and an in-phase current passing through them, which results in further power losses in the form of heat.

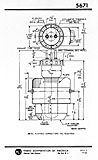

The filaments in the finals and modulator tubes, each require 11V at 285 A = 3135 watts of power. For all four

5671s which must be in operation that's 4 * 3135 = 12,540 Watts just to light the tubes.

In a class C, RF amplifier, each tube in a push-pull arrangement alternately "kick" energy into the tank

circuit from one end to the other. The actual energy pulses from each tube are full of harmonics as the current

waveform is very non-sinusoidal. The tank circuit acts like a pendulum, swinging back and forth in a near sinusoidal

fashion. It is a combination of inductive and capacitive reactances, alternating the current flow at a the resonant

frequency of the combination. In this case the two components are in parallel, forming an anti-resonant circuit,

which shorts out (filters) frequencies, which are not at the resonant frequency. (Try making a clock

pendulum or playground swing move at a rate which is not at it's natural or resonant frequency.) In this case the

energy is transferred or magnetically coupled via a secondary coil "link coupling." All transmitters,

modern and old, use the same principles of resonance, to transfer a radio frequency, which centers on the dial

position of the radio station.

The Harris MW-50 takes a step to reduce the losses by operating the modulator

tube(s) at either saturation (maximum current at nearly zero volts) or cutoff (maximum voltage at nearly zero current).

Any way you cut it, with ohms law E*I = W, either E or I is nearly zero, yielding a low amount of power loss in

the modulation tube. How does this translate to audio? When unmodulated, the modulation tube is generating a square-wave

at, say, 70 Khz. With no modulation, the time duration of the "on" portion is equal to the time duration

of the "off" portion of the waveform, yielding an unvarying "middle" average. The 70 Khz is

filtered out in coupling to the final amplifier. When modulated, the square wave duty cycle is varying in accordance

to the audio. At maximum peaks, the square wave has wide, on-cycles and and minimum peaks, the tube has wide, off

cycles. The varying duty cycle creates an AVERAGE voltage and current, which corresponds to the audio. It is coupled

through a 70 Khz low pass filter to the the RF finals. This is much like a modern light dimmer, which simply chops

the power at either longer or shorter intervals. The light bulb, itself has a thermal time constant (it cannot

instantly cool or heat), which filters out the chopped part. This type of modulation is called PWM or Pulse Width

Modulation.

The Harris DX-50 takes a whole different approach, but extends the idea of operating devices in either saturated

or cut-off states. This method, invented by the late Hilmer I. Swanson 1932-2005, completely eliminates transformers,

except for the output coupling network (thousands of pounds, Watts, and cubic feet). It is also completely solid

state, eliminating filament power (you can't heat the building on a cold day with a DX-50). The DX-50 takes the

approach of using hundreds of small RF modules, stacked to add up to the total power output of the transmitter

at any instant. To modulate the transmitter, the RF modules, each square wave amplifiers, are turned on or off

in accordance with the modulating audio. The modulating audio control is accomplished by a set of solid state boards,

which can all fit in a PC sized box. These boards convert the incoming analog signal to a digital representation,

which, in turn passes through logic to control the output amplifiers. Each module is small enough to be held in

your hand. All modules are coupled to a common buss via toroids to add up the total output power. The harmonics

of the square wave are lost through filtration, leaving the carrier frequency and its sidebands. If one of the

modules fails, the transmitter continues to operate at almost full power.

About 5 years ago, one engineer told me that he was saving about $9,000.00 per month by switching from the old

plate modulated 50KW transmitter, to the DX-50. By this time, there are even more advances in transmitter design,

allowing these solid state transmitters more flexibility in expansion and the automatic substitution of modules

by spares if a failure occurs.

There are other manufacturers of efficient, solid state transmitter, which use slightly different, but efficient

approaches. Nautel is one of them.

The DX-50 and newer transmitters lend themselves to a very simple hookup for expansion to HD (High Definition)

modulation. The bigger difficulties may be in some output and antenna networks, but, often very little if any change

is necessary.

WOWO started using HD on the AM band on April 4, 2005.

HD (IBOC) is further explained on my WOR page and the Harris DX-50 is further

explained on my WABC NOW page.

The one loss that has occurred with new technology is the AWESOMENESS of the large and roaring, engine-room feel

and the Art Deco "56 Chevy Chrome and Glass" factor. Another change is that transmitter engineers and

technicians maintaining these new, reliable transmitters, find themselves maintaining not one, but many sites.

Their jobs have become regional with more travel involved.

...Jim Hawkins

|